Chromite is a key raw material in industries such as stainless steel and high-end alloys. How can we maximize the utilization of this resource through efficient separation technology?

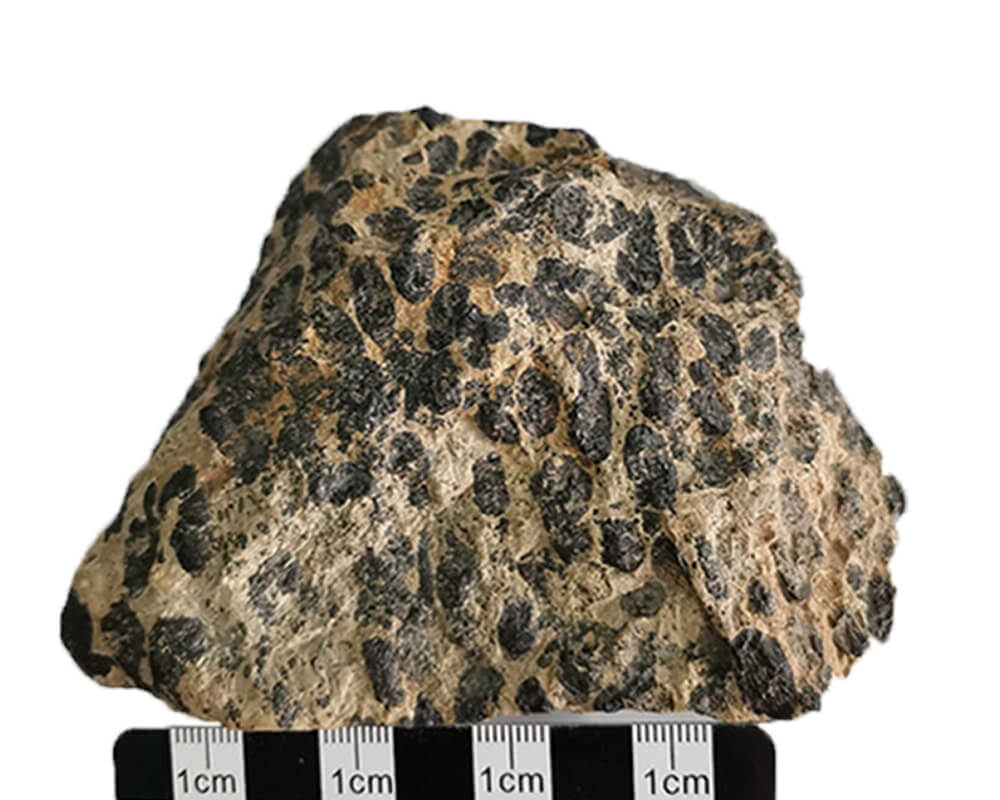

This not only concerns improving ore grade but also directly impacts the economic benefits of subsequent smelting. Chromite often contains numerous impurities, such as silicates and iron minerals, some with particle sizes as fine as dust, and others exhibiting vastly different magnetic strengths. Directly applying fixed separation processes often fails to achieve the desired recovery rate and grade balance. Therefore, determining the optimal separation technology through targeted beneficiation testing is a crucial step in improving the utilization rate of chromite resources. This article will systematically analyze the most commonly used separation technologies in chromite testing, helping practitioners quickly select and optimize process parameters, providing a reliable reference for industrial production.

Which separation technology is best suited for your chromite ore testing? Flotation is suitable for fine-grained disseminated ores; gravity separation is used to separate coarse-grained ores; magnetic separation is used for the enrichment of magnetic minerals; and combined technologies are suitable for the beneficiation of complex ores. Efficient separation methods are key to improving chromite grade and recovery rates. We will customize a solution based on your ore, throughput, budget, and other information.

Table of Contents

What is Chromite Testing?

The core value of chromite testing lies in simulating key conditions of industrial production in a laboratory environment, such as ore particle size, reagent ratios, and equipment parameters, to verify the practical feasibility of separation technologies in advance. In chromite beneficiation, the main separation technologies include flotation, gravity separation, and magnetic separation. By implementing these testing methods systematically in the laboratory, key process parameters can be obtained, providing a reliable basis for the subsequent design of industrial beneficiation plants.

In actual production, different separation methods can lead to significant differences in recovery rates and concentrate grades. Skipping testing and directly applying it to industrial production may result in serious losses due to the mismatch between ore characteristics and technology. For example, using magnetic separation to process non-magnetic chromite results in a recovery rate of less than 10%, and also leads to equipment idleness and resource waste. Therefore, testing serves as a bridge between laboratory research and industrial applications, effectively mitigating technological risks.

Why is Separation Technology Necessary?

The choice of separation technology directly affects three core production indicators: recovery rate, grade, and cost. Increased recovery rate means more resources are utilized, improved grade enhances product competitiveness, and reduced costs directly increase profits. Conversely, choosing the wrong technology can trap companies in a vicious cycle of “low recovery rate, low quality, and high cost.” An ideal separation solution should optimize economic benefits while meeting market demands for product quality. Therefore, the core objective of testing is to find the optimal balance among these three factors.

Mainstream separation technologies in chromite testing

1. Flotation Separation Test

An Efficient Enrichment Method for Fine-Grained Chromite

Flotation separation technology is mainly based on the differences in the physicochemical properties of mineral surfaces, achieving the separation and enrichment of target minerals through selective reagent adsorption. Chromite naturally has a weakly hydrophobic surface, while gangue minerals such as quartz and feldspar are hydrophilic. By adding a collector, the hydrophobic groups are selectively adsorbed onto the chromite surface, further enhancing the hydrophobic properties, while the hydrophilic groups gravitate towards the aqueous phase. Simultaneously, a frother generates stable foam under stirring. The hydrophobic chromite particles adhere to the foam and float to the surface to be scraped off, while the hydrophilic gangue remains in the slurry.

Flotation testing is mainly used for the efficient enrichment of fine-grained or low-grade chromite.

2. Gravity Separation Test

A Classic Method Based on Density Differences

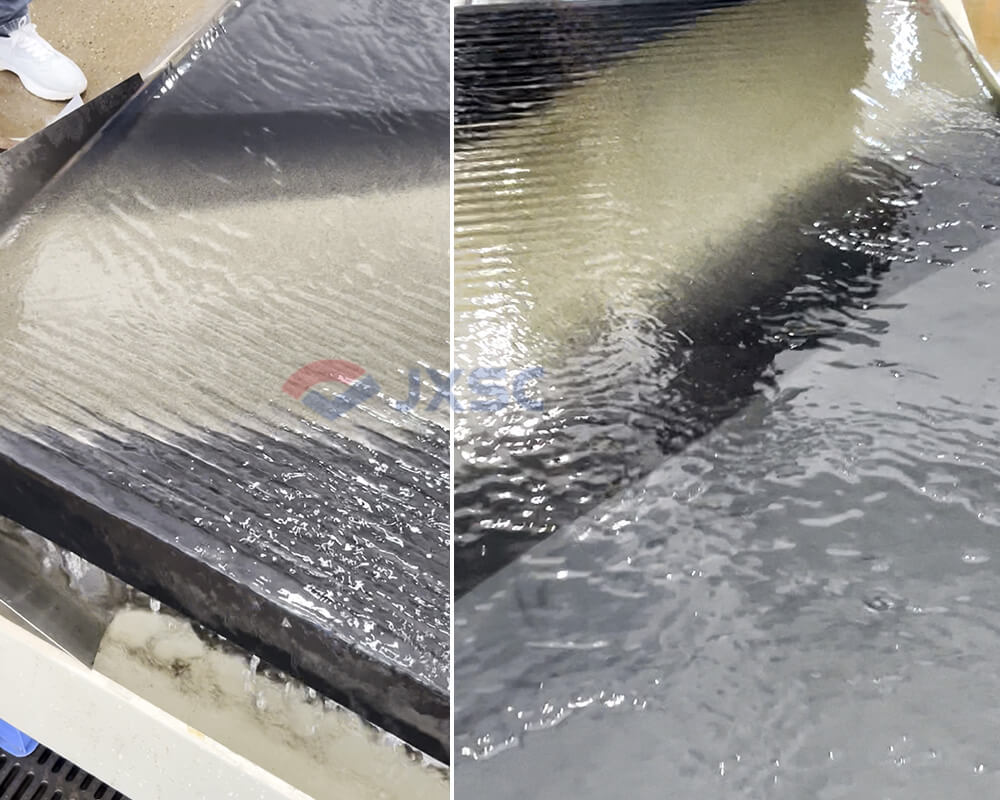

The core logic of gravity separation testing is to achieve precise stratification based on the density difference between chromite and gangue minerals. Chromite typically has a density between 4.3 and 4.8 g/cm³, much higher than gangue minerals such as quartz and feldspar. In an aqueous medium, gravity separation equipment creates stratification conditions through the movement of water flow (such as pulsation, vibration, and centrifugal force): denser chromite particles are more strongly influenced by gravity and will settle to the lower layers or accumulate in specific areas of the equipment. Denser gangue particles move upwards or outwards with the water flow, thus achieving separation. Before testing, it is best to perform particle size analysis on the ore to determine the optimal feed particle size range. Gravity separation testing verifies the feasibility of chromite gravity separation technology under different conditions by simulating this physical stratification process, and is a classic and efficient method for processing coarse-grained chromite.

Commonly Used Testing Gravity Separator

- Shaking tables are primarily used for separating fine-grained minerals. Combining inclined water flow and bed vibration, chromite particles accumulate in the enrichment zone on the bed surface, while gangue is discharged from the tail end with the water flow.

- Spiral chutes are suitable for processing fine to micro-fine-grained minerals. Utilizing the combined forces of centrifugal force and gravity, high-density chromite settles along the inner side of the chute, while gangue flows out along the outer side.

In chromite testing, the selection of laboratory equipment must match the ore particle size and separation requirements. Testers can adjust the crushing and grinding parameters of the ore sample to control the feed particle size within the optimal range. Coarse particles can be treated with gravity separation, or fine particles can be treated with a combination of techniques, such as flotation to improve the overall separation effect.

3. Magnetic Separation Test

Precise Separation of Magnetic Chromite

The core logic of magnetic separation technology is to achieve separation by utilizing the magnetic differences between chromite and gangue. Some chromite (such as magnetite-type chromite) is strongly magnetic, while gangue, such as quartz and feldspar are mostly non-magnetic or weakly magnetic. In the laboratory, when the slurry flows through the magnetic field area of other laboratory magnetic separation equipment, such as magnetic rolls or small dry magnetic separators, strongly magnetic chromite particles are attracted by the magnetic poles, detach from the magnetic field, and collected. Weakly magnetic/non-magnetic gangue is discharged with the water flow.

Key Parameters:

During the chromite testing process, various Gaussian gradients need to be tested. A magnetic field that is too weak will not attract weakly magnetic chromite, while a magnetic field that is too strong will easily entrain gangue, reducing the grade. Precise control of the magnetic drum speed and slurry flow rate is also required to achieve efficient separation of magnetic minerals and non-magnetic gangue.

This magnetic separation method avoids excessive consumption of chemical reagents and is suitable for removing strongly magnetic minerals mixed in during the mining process, which can increase the grade of chromite concentrate by 1-2 times. It is especially suitable for processing high magnetic chromite.

4. Combined Separation Technology Testing

Comprehensive Solutions for Complex Ores

For complex ores that cannot be addressed by a single technology: Magnetic separation + flotation is suitable for weakly magnetic fine-grained chromite—magnetic separation removes strongly magnetic gangue, reducing flotation reagent consumption, while flotation enrichment solves the problem of weakly magnetic fine-grained ores. Gravity separation + magnetic separation technology is suitable for coarse-grained ores—gravity separation provides rapid roughing (high efficiency and low cost), covering both coarse-grained separation and precise purification.

How to Choose the Appropriate Separation Technology for Chromite Testing?

Ore Characteristics:

If the chromite is strongly magnetic (e.g., magnetite type), magnetic separation should be prioritized. For processing low-grade ores with fine-grained disseminated ore, flotation is more efficient. For processing coarse-grained, massive disseminated ore, gravity separation is the economical choice.

Target Grade:

If the company prioritizes resource utilization, a combination of gravity separation and magnetic separation can be chosen, balancing recovery rate and cost. If targeting the high-end market, flotation should be used to improve the grade; even if the recovery rate decreases slightly, it can be compensated for by higher added value.

It is best to first perform mineral composition analysis, using X-ray diffraction to determine gangue type, magnetic analysis to measure magnetic strength, and particle size distribution to clarify particle size distribution, providing data support for technology selection. Simultaneously, the disseminated state determines whether a combined technology is needed. For example, for fine-grained, weakly magnetic ores, flotation + magnetic separation is suitable; for coarse-grained, strongly magnetic ores, gravity separation + magnetic separation is recommended. Specific separation technologies need to be customized based on your mineral information to avoid wasting resources through blind testing.

In chromite testing, separation testing techniques are crucial for the efficient enrichment of low-grade, fine-grained, or complexly disseminated chromite. Flotation is suitable for enriching fine-grained minerals, gravity separation achieves classic separation based on density differences, magnetic separation precisely separates magnetic minerals, and combined separation testing solves complex ore problems that cannot be addressed by a single technology. Contact the experts at Asia-Africa International (JXSC), and we will customize mineral processing testing equipment and services by combining ore characteristics and target indicators, balancing recovery rate, grade, and cost!