Service Costs

Laboratory Mineral Dressing Testing Charges

Asia-Africa International divides the mineral dressing into six types: exploratory testing, beneficiability evaluation testing, laboratory process test, enlarged-scale laboratory continuous test, pilot-scale test, and industrial scale test.

- Fast Access to Lab Test Fees

- Exploratory Testing

- Beneficiability Testing

- Lab Process Test

- Enlarged-scale Lab Continuous Test

- Pilot-scale Test

- Industrial Test

Mineral Dressing Testing Costs

Exploratory Experiment

Use the most mature methods, processes, and chemicals to process the ore. The exploratory testing fee is generally $150-$2500. If the mine is complex, the cost will be higher.

Beneficiability Evaluation Testing

A beneficiability evaluation testing is a mineral processing experiment to evaluate whether ore has value or to explore the mineral processing method of ore to save costs. The beneficiability evaluation helps to improve the concentrate grade and reduce the tailings grade. As for how high the concentrate grade can increase, how high the recovery rate is, how low the tailings grade can reduce, whether it can be lower, and whether there are better methods and processes, pharmaceutical conditions, etc., we can’t get the answer from beneficiability evaluation testings. Because beneficiability testings are generally not done with continuity tests.

The beneficiability evaluation testing generally charges between $4,500 and $13,000, according to the nature of the ore. Large scientific research units generally charge higher fees, and small scientific research units generally charge lower fees. At the same time, the charges are also different according to the nature of the ore. Generally, the costs for complex, fine-grained, and difficult-to-select ores (such as polymetallic sulfide ores, oxide ores, etc.) are higher. In contrast, the costs for single, coarse-grained, and easy-to-select ores are lower.

Laboratory Process Test

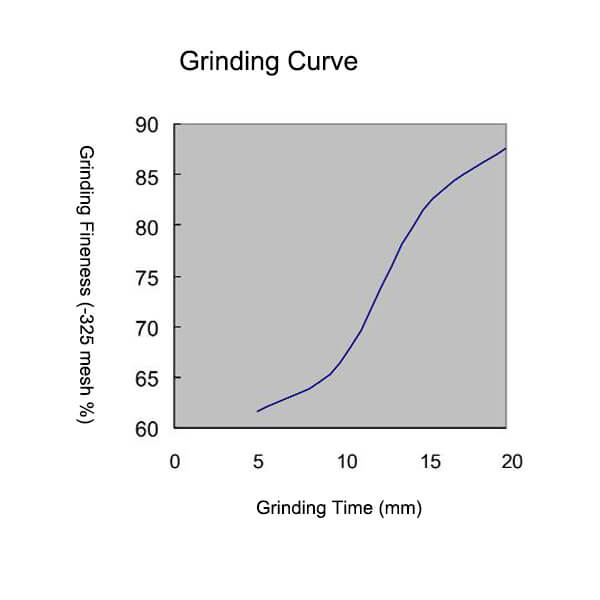

The laboratory process test can tell us a lot of data, such as the appropriate grinding fineness, the best chemical conditions (medicine type, dosage, adding order, adding place), the best process, the impact of the backwater, etc.

The laboratory process test did all the processes required for the beneficiation test, including the grinding fineness, the type & dosage of the absorbing agent types, the type & dosage of the regulator(including acid-base, inhibitor, activator, etc.), the dosage of the foaming agent, the stages of featured and sweep selection, the type of agents, dosage, adding order, flotation time, the impact of the backwater, etc. of each stage. The most important thing is that the laboratory process test must meet the indicators mentioned by the sample sender.

Depending on the nature of the ore, the laboratory process test charges between $15,000 and $80,000.

Enlarged-scale Laboratory Continuous Test

Unlike laboratory process tests, the enlarged-scale laboratory continuous test is larger, the mine is constant, it can simulate industrial equipment more correctly, and the test process can continue in a stable state. Therefore, the test conditions and results are relatively close to industrial production and can identify and determine some factors and parameters that cannot be identified and determined under laboratory conditions, such as equipment models, operating parameters, and consumption quotas. The processing capacity of the enlarged-scale laboratory continuous test is generally 0.1-5t/d. The test fee is typically between $45,000 and $80,000.

Pilot-scale Test

The pilot-scale test is an enlarged version of the enlarged-scale laboratory continuous test, which processing is larger, and can reach 50-100t/d. Its test process is closer to industrial-scale production, and the data obtained are more representative of industrial production data. The pilot-scale test charges are generally between $45,000 and $160,000.

Industrial Scale Test

There are generally two types of industrial scale tests (commercial use test), one is pure industrial test, and the other is industrial debugging. The industrial test is generally done in the concentrator, and industrial debugging accounts for the vast majority. The so-called industrial commissioning means that the entrusted party sends staff to the authorized party’s dressing plant to carry out production under the conditions of industrial production scale according to the process flow and requirements provided by the entrusted party and make the equipment run continuously and stably for some time to inspect the production status and adjust the process conditions or processes to achieve the technical indicators required by the entrusting party. The fees for industrial trials are generally between $80,000 and $160,000.

For more details on charges or costs, please get in touch with us.