Do you know what is the most critical factor for a gold mine to be developed efficiently? Gold is not only the core material of jewelry, but also the key conductor of the electronics industry and an important part of the country’s foreign exchange reserves. It is the core raw material supporting the modern financial system and high-tech industries. The accurate testing of gold ore directly determines the economic value of the mineral, environmental compliance, and even the success or failure of the entire beneficiation plant project. Gold mine laboratory testing is an experiment used to evaluate the selectivity of gold-containing ores, that is, to determine how to extract gold from the ore effectively. These tests include a variety of methods, such as XRF analysis, grinding fineness test, flotation test, etc., aimed at determining the most appropriate beneficiation process and parameters to improve gold recovery and reduce costs.

There are five major steps in gold ore lab testing: sampling to ensure representativeness; preparation to make the sample uniform; analysis to determine the gold content and state; quality control to ensure the reliability of the results; and reports for resource assessment and process design. Mastering these steps can accurately control the test and provide a strong basis for gold mine development.

Table of Contents

Gold ore lab testing step 1: Sampling

Sample collection is the basis of gold mine laboratory testing. Good samples can accurately reflect the overall characteristics of the gold mine. If the collected samples cannot represent the entire deposit, no matter how accurate the subsequent test results are, they may lead to misjudgment of the value of the gold mine, which in turn affects the mining decision, resource planning and economic benefits of the gold mine. Excellent sample collection must meet three core requirements: representativeness, uniformity, and pollution prevention.

Collection methods and considerations

If it is a porphyry gold mine, etc., the open-pit sampling method can be used. If it is a vein gold mine, etc., the underground mine sampling method can be used.

- Sampling location: The points should be selected according to the geological characteristics and ore distribution, covering different layers, locations and types. For example, multi-layer ore bodies should be sampled from each layer.

- Sampling quantity: It depends on the scale of the gold mine, the uniformity of the ore and the test requirements. The more the number, the better the representativeness, but it should be determined reasonably to balance the cost and workload.

- Sampling frequency: Gold mines with large changes in ore properties need to increase the frequency, such as adjusting with depth and regional changes during mining.

From selecting a sampling plan that meets the mineral processing test specifications to implementing sterile anti-contamination measures, every detail may affect the authority of the final report. Mainly based on the gold mine type test method, strictly control the location, quantity, and frequency, and properly transport and store them to avoid moisture, oxidation, and contamination to ensure sample representativeness and test accuracy.

Gold ore lab testing step 2: Sample Preparation

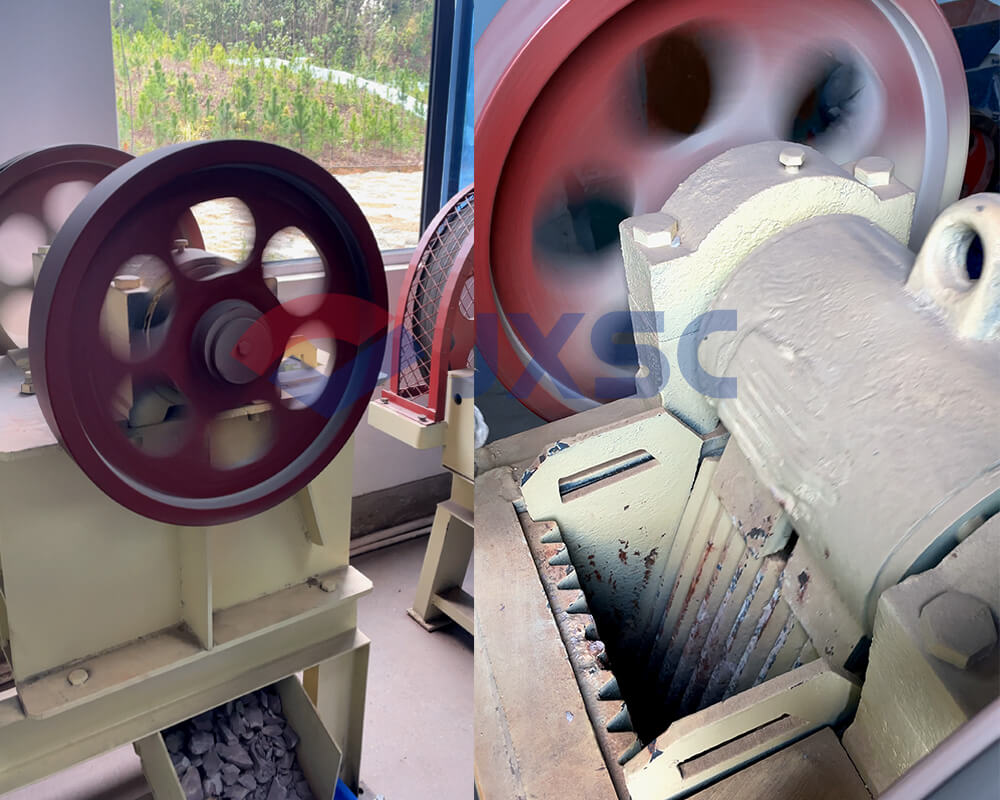

Crushing and grinding

Purpose: Gold ore samples often exist in different particle sizes and forms in nature, and the internal components are unevenly distributed. Crushing and grinding can make the sample particles smaller and more uniform in size, so that gold elements and other components are more evenly distributed in the sample. At the same time, increasing the surface area of the sample allows the sample to contact and react more fully with the reagents during the subsequent analysis process, thereby improving the accuracy and reliability of the analysis.

Main equipment and key points

- Jaw crusher: According to the initial particle size and hardness of the sample, the width of the discharge port between the jaw plates should be reasonably adjusted. The general discharge particle size is controlled at 10-50 mm. The wear of the jaw plates should also be checked regularly. If the wear is serious, they should be replaced in time to ensure the crushing effect.

- Roller crusher: Suitable for medium crushing process. During operation, it is necessary to pay attention to uniform feeding to avoid segregation, and at the same time control the feeding amount to prevent equipment overload.

- Laboratory ball mill: Used for fine crushing and grinding, it is to impact and grind the sample in a rotating cylinder through steel balls. The ball loading, ball size ratio and cylinder speed are the key factors affecting the grinding effect. Usually the ball mill can grind the sample to less than 74 microns.

Gold ore lab testing step 3: Analytical

Chemical analysis

Chemical analysis is the basis for evaluating the economic value of gold mines, providing a basis for mining, mineral processing, and cost control. By determining the content of gold and associated elements, the mining value can be judged and the comprehensive utilization of resources can be guided.

Mainly used are atomic absorption spectroscopy and inductively coupled plasma mass spectrometry. Among them, atomic absorption spectroscopy is suitable for trace component analysis, and can measure most metal and metalloid elements, but it is difficult to measure multiple elements at the same time. Inductively coupled plasma mass spectrometry is to ionize the sample elements and then analyze them by mass spectrometry. It can measure more than 100 elements at the same time and is widely used in many fields.

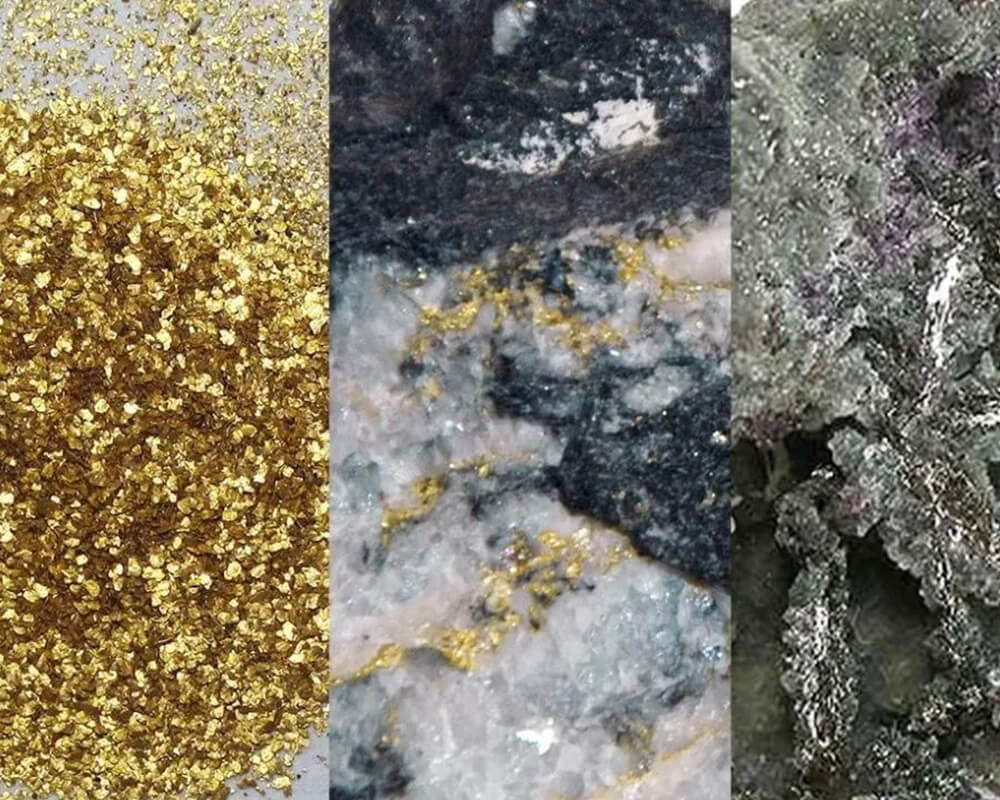

Mineralogical analysis

Mineralogical analysis is mainly to understand the mineral composition and structure of gold mines, determine the occurrence state of gold, and provide a basis for the design of mineral processing technology.

Usually, a microscope is used to directly observe the mineral morphology and embedding relationship, judge the occurrence and distribution of gold, and guide the mineral processing technology. X-ray diffraction analysis is used to identify mineral components and determine the content ratio to provide information for comprehensive evaluation and process design.

Gold ore lab testing step 4: Quality control

Ensure that the test data is authentic and reliable, reduce errors, ensure the accuracy of the results, avoid decision-making errors and economic losses, enhance the credibility and authority of the laboratory, and help build a standardized management system.

In the gold mine laboratory test, standard substances with similar properties to the gold mine samples are used together with the actual samples for testing. By comparing the test results of the standard substances with the known values, it is determined whether there are errors in the test process. If the test results are within the uncertainty range of the standard substance, it means that the test method is reliable, otherwise the test process needs to be checked and adjusted.

Repeated testing can evaluate the repeatability and stability of the test results. If the difference between multiple test results is within a reasonable range, it means that the test process has good repeatability and stability; otherwise, there may be problems such as unstable test methods and inconsistent technical levels of operators, and further investigation of the causes is required.

Gold ore lab testing step 5: Report and interpretation

The test report mainly contains sample information, test methods, element content results, uncertainty, standard substance information, and preliminary evaluation conclusions and suggestions. Combined with industry standards, the test results are interpreted to determine the element content, occurrence state, etc. It is mainly used for resource assessment and determination of mining feasibility, mineral processing method decision-making, etc.

- Gold mine resource assessment: Based on the gold content, ore grade and other indicators in the test results, the resource reserves and economic value of the gold mine are assessed. At the same time, a reasonable mining plan is formulated in combination with the geological characteristics of the ore deposit, mining conditions and other factors.

- Ore dressing process selection: The mineral composition, gold occurrence state, and other information in the test results are of great guiding significance for the selection of the ore dressing process. By analyzing this information, the appropriate ore dressing method can be determined to improve the gold recovery rate and beneficiation efficiency.

Summarize

These five key steps of gold mine laboratory testing, from sample collection, sample preparation, analytical testing, quality control to report interpretation, are closely linked, and each step plays a decisive role in the accuracy and reliability of the final test results. Accurate test results can provide a solid basis for gold mine resource assessment, mining plan formulation, and mineral processing technology selection. Whether it is the accurate judgment of reserves and value during resource assessment, or the scientific selection of mining plans and processes in project decision-making. Welcome to contact us (Asia-Africa International (JXSC) ), we can provide customized mineral processing testing services and equipment.