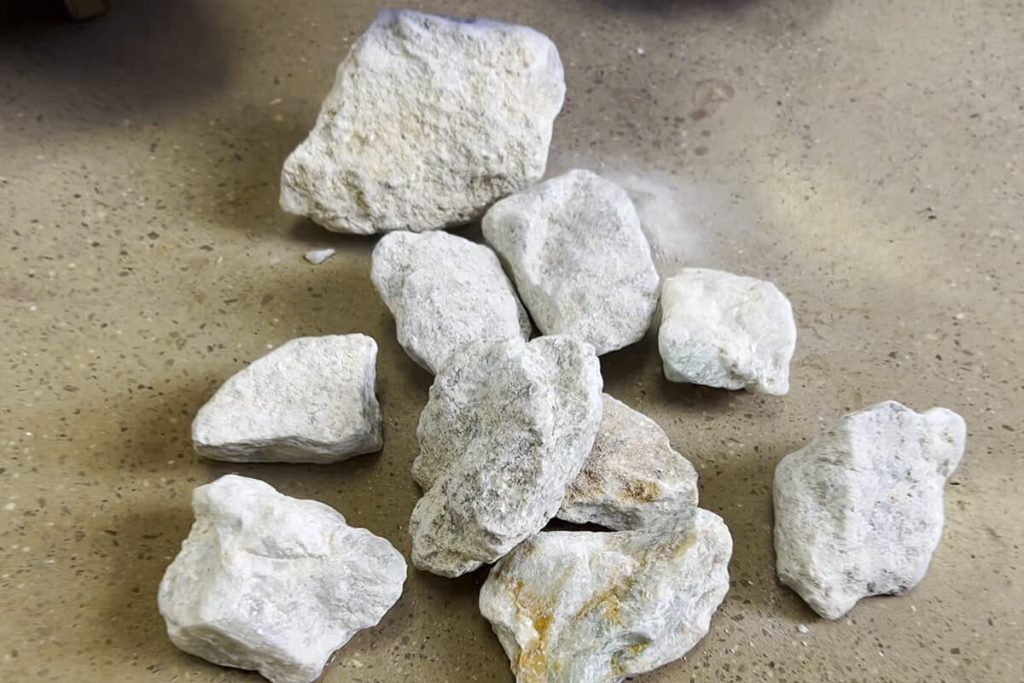

Fluorite ore, also known as fluorspar, is a mineral composed of calcium and fluorine. Fluorite minerals, with their vibrant colors and unique fluorescence under ultraviolet light, are visually stunning and play a vital role in industrial applications such as metallurgy, chemistry and glassmaking. However, it must undergo a rigorous laboratory testing process before it can be used commercially. This ensures that the ore meets specific quality standards and helps determine the most appropriate processing method. We will analyze the fluorite ore laboratory testing process and discuss the equipment needed to obtain accurate results. By understanding this testing procedure and utilizing the appropriate tools, researchers and professionals can enhance their understanding of the composition of fluorspar ore to optimize production processes, improve product quality and effectively meet industry standards.

Fluorite Ore Analysis

Determine the distribution of various particle size levels in the ore by screening or laser particle size analysis. The material is then analyzed for mineral composition and chemical composition.

Fluorite ore composition test can understand the chemical composition and impurity content present in the ore. This information is critical for optimizing extraction methods, assessing economic viability, and ensuring compliance with quality standards.

- First, collect fluorite ore samples and conduct preliminary tests on them to understand the properties of the original ore and the distribution of valuable minerals in the ore.

- Conduct mineralogy identification to determine the types of valuable minerals in the ore, such as fluorspar, quartz, calcite, etc.

- To test the physical properties of the ore, such as density, magnetism, etc., for the selection of the subsequent beneficiation process.

To test the composition of fluorspar ore, the following are common equipment used to test the fluorspar ore composition:

- Spectrometer: Determine the elements or functional groups in the sample by measuring the spectral characteristics of the fluorite sample.

- X-ray Fluorescence Spectrometer (XRF for short) is a commonly used analytical instrument. The sample container is placed in an XRF instrument, and by bombarding the sample with X-rays and measuring the energy and intensity of the resulting fluorescent radiation, elemental information present in the ore can be identified and quantified.

- Atomic absorption spectrometer (AAS): AAS can analyze the content of metal elements in the sample, such as calcium, lanthanum, etc.

- X-ray diffractometer (XRD): This is very helpful in understanding fluorite’s crystallization state and impurity content. By irradiating X-rays, the ore will diffract to form a specific diffraction pattern, so the crystal structure in the ore can be determined.

Fluorite Ore Test Process & Equipment

The beneficiation test of fluorite ore is to obtain the concentrated product of valuable minerals in fluorite ore to improve its grade and recovery rate further. The following is a general laboratory fluorite ore beneficiation test process and equipment that may be used:

1. Sample Preparation

Obtain samples of fluorspar ore from mining sites and ensure sample representativeness. Fluorite ore must undergo a series of crushing processes to reduce its size to obtain samples of suitable particle size. Commonly used lab jaw crusher, its sturdy design and powerful motor allow it to process high hardness ore easily. Then use lab hammer crusher to crush and obtain ultra-fine materials by colliding between the hammer head and the rock.

Grind the collected fluorite ore samples to make the particles fine and uniform. The ore is typically ground using a laboratory cone ball mill or other suitable grinding equipment. With adjustable speed settings, scientists can precisely control the grinding process to achieve desired results. Laboratory disc mills are also available, whose high-speed rotation of the grinding discs ensures that even hard or brittle ores are quickly crushed into a fine powder.

Put the fluorite ore into the jig separator, the sawtooth wave first rises in a straight line, then falls, repeating the cycle. It uses water as the beneficiation medium and sorts according to the specific gravity difference between fluorite ore and gangue. After a short period of treatment, fluorite concentrate can be obtained.

The fluorite ore beneficiation mainly adopts the flotation process, which uses the difference in characteristics between fluorescent and other minerals to suspend and desorb fluorite minerals through chemicals such as flotation agents. It usually includes rough flotation, fine flotation and recovery flotation to determine the best flotation process parameters. In the experiment, common flotation equipment includes flotation machines, stirring tanks, etc. Find the best flotation conditions by adjusting the type and amount of flotation agents, stirring speed, flotation time and other parameters.

- Flotation concentrate treatment: The coarse ore slurry obtained from the flotation test is subjected to secondary grinding to refine the ore particles further. The ore pulp after secondary grinding is selected to remove impurities and non-useful minerals to obtain flotation concentrate.

- Tailings treatment: The flotation concentrate may also contain some impurities and non-useful minerals that have yet to be separated, and tailings treatment is required. The flotation tailings treatment process removes unnecessary parts from the slurry to meet the requirements of resource recovery and environmental.

5. Test data analysis

Analyze and calculate test data, including beneficiation grade, recovery rate, beneficiation index, etc. Evaluate the effectiveness and economy of the beneficiation process based on the test data, and optimize the process conditions.

6. Result report

Organize the test results into a report, including test steps, equipment types, data analysis and conclusions, etc. The mineral processing process and improvement suggestions are put forward according to the mineral processing test results.

The above process and equipment can help laboratories and scientific researchers to accurately determine the properties of fluorite ore, so as to determine its mineral processing value and application better. The beneficiation test needs to strictly control the test conditions and operations to ensure that the results are accurate and reliable, and provide a reference for the follow-up process design and production of fluorite mines. If you are looking for suitable processes and equipment, we will analyze according to your specific testing needs, budget, laboratory conditions and provide the most effective laboratory solutions.